We get this question a lot: “Company XXX sells motors with a super high stall torque (oz-in) rating — won’t I get better performance from these higher torque motors”? The answer may surprise you!

Unfortunately, the main statistic advertised on linear step motor or nema 34 closed loop stepper motor is probably the least useful of all — stall (or holding) torque, which is the torque the motor puts out when it is not moving. This isn’t terribly helpful, as your motor isn’t doing any work when it’s standing still! All steppers run at less than their stall torque, so what’s far more important is the usable torque of the motor throughout its RPM range. The “flatter” this torque curve, the more usable force (for accelerating and decelerating) you’ll get out of your drive system.

All stepper motors also put out less torque the faster they rotate. There are two key values that you should be looking for in a motor that influence its performance: current and inductance. First of all, you should look for a motor with a current rating that is less than or equal to the current rating of your motor driver. Motor torque scales linearly with current, so if you are (for example) driving a 5A motor at 3.5A (the maximum the G540 drive can put out), you are only getting 70% of the motor’s rated torque. All other things being equal, a 425 oz-in, 5A motor running at 3.5A will actually achieve less torque than our 420 oz-in motors running at 3.5A.

The other important thing to look for is the motor inductance. The lower the inductance, the slower the motor builds up “back EMF voltage”, which reduces the torque of the motor. While higher inductance can be overcome with higher voltage power supplies, this adds extra heat and expense to a system.

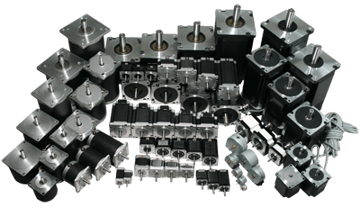

We invite you to look at competitor offerings, and see for yourself why our motors are better. We offer motors that are matched to the current ratings of the drivers we sell. Our motors are also low inductance, 2 mH for our 960 oz-in motors and 3.0 mH for our 420 oz-in motors, both of which work great with commonly available 48V supplies.

So don’t fall for the hype — with our motors, we’ve had customers gain 3x speed increases over motors with higher rated stall torques. We’ve tested our motors and competitor motors with our mechanical systems to find the best value for you. Buy from a name you can trust to get the most out of your machine.

https://izidental.page.tl/Accuracy-or-Repeatability-of-2-or-4-Phase-Stepper-Motor.htm

https://www.kontrolkalemi.com/forum/konu/nema-23-step-motor-bilgi.120430/